Seal Packing Installation Guide

1.Installation preparations

Removal of the old filler packing box is a kind of pre-inspection preparation for the installation of the key elements.

Packed with old before they fill all out with special tools to stuffing box. Wipe clean. Stuffing box observe whether the defects such as eccentric injury, stem injury, bushings and stuffing box can affect performance of packing. Also check whether other parts. Replace all the defective parts.

2. Choose a suitable packing

Packing in the selection must be taken into account two things.

Packing condition and performance requirements should match. According to the relevant technical data can be selected to meet the requirements of the Packing. If in doubt, consult a sales representative.

Seal requirements must be based on the correct choice of Packing’s Size. In order to determine the cross-section, please use the following formula calculations: Cross-section=( Stuffing box Diameter- Stem Diameter)/2

In order to compensate for injury may require the installation more larger cross-section of thepacking.

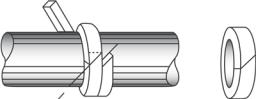

3. Cutting and installation

Cut off by cutting mechanical precision required length of the Packing ring. If there is none of mechanical,underL=(D+S)X1.07X丌 for cutting. General rotation axis, with 90 ° cutting straight; valves on the cutting 45 °. Never attempt to stuffing box with packing around to determine the length. Otherwise will be in the Packing around the same with the stem of a pipe OD, and it"s tightly repressed, but not tensile it. Then cut its kind ring

, and test whether it can accurately fill space. And ensuring that its interface does not have gaps. Central then can be used like other cutting as a standard packing rings. If these products in the plane completed, if the packing is soft or easily deformed, can be produced in accordance with a small ring-like scallops, and then according to the rope to produce the remaining filler ring.

When the packing for valve, packing section’s space and the same of the valve, surcharging central is the best.when for pump, packing section and valve space, packing to a shaft and a leaking space is conducive to lubrication and cooling.

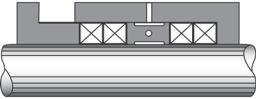

One-time installation packing rings, must fill each convinced that no dust or other debris viscosity. If you need, packing rings should be used in stem on the same clean lubricating oil to be. Each installation staggered packing rings 90 °Central started slowly in the axial, the radial distance to axis can be loaded to the central. Fill tool use professional to fastening packing rings. When the installation is complete,grand stretched its valve on the Stuffing box until 25% of the thickness of packing, pump 50% of the thickness. Follow-up pieces use of its closed, can increase tightness. Remember, follow-up pieces were only as a supplement, cab ensure that all appropriate packing rings position to avoid packing mobile.

Reciprocating pumps, fill the box at both ends and intermediate orientation should Add to Central, to maintain its concerted campaign by the plunger and gravity.

4. Rotating and reciprocating pump start

Before operation, Load first state in the absence of commissioning,Observation of atypical,then official car, careful observation, there is no pressure or hard.and causing serious leak or burn filler phenomenon. Pump startup that is the key to its leakage at the beginning. If one started to leak Pan-gen without fastening to the state, will lead to leakage burns packing.

Fill in the ring after installation, twisting bolts, and recognizing the filler material covered me with the right of joint. Once Bolt, it is necessary to ensure that all the bolts of the uniform.

If the application of an external lubrication system, that should be prior to the commencement of its operation to correct.

Startup allows leakage rate. In the process, the Pan-gen Yasui and begin work.

After running about 15-30 minutes, until once again Setscrew allowed to leak. Recommended leakage of 8-10 points / minute. Tetrafluoroethylene filler should be allowed to export a greater flow of heat to reduce thermal expansion.

5. Valve launched

Most, zero leakage valve design.In order to achieve this, we must refer to the pressure valve in the fastening of the filler completely.

6. Valve Installation Guide with Packing

a. Pump used in strict accordance with the Pan-gen Installation Guide to operate;

b. Rotating around the valve to ensure that the bolt free rotation;

c. Check valve operation, if found leakage reference to the relevant safety procedures and maintenance vendors recommend appropriate adjustments.

|